THE TOUR ENGINE IS A PATENTED, SPLIT-CYCLE, INTERNAL COMBUSTION ENGINE THAT STANDS TO DELIVER SUBSTANTIAL EFFICIENCY GAINS THROUGH SUPERIOR THERMAL MANAGEMENT

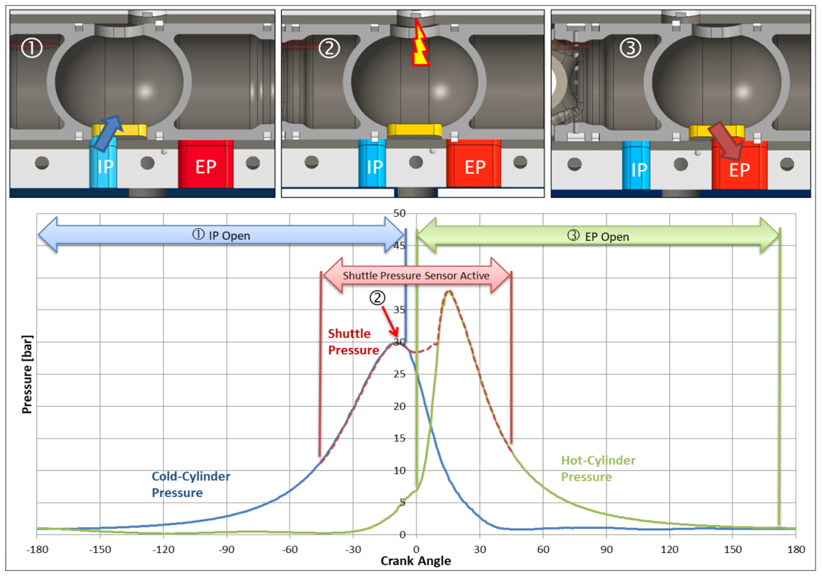

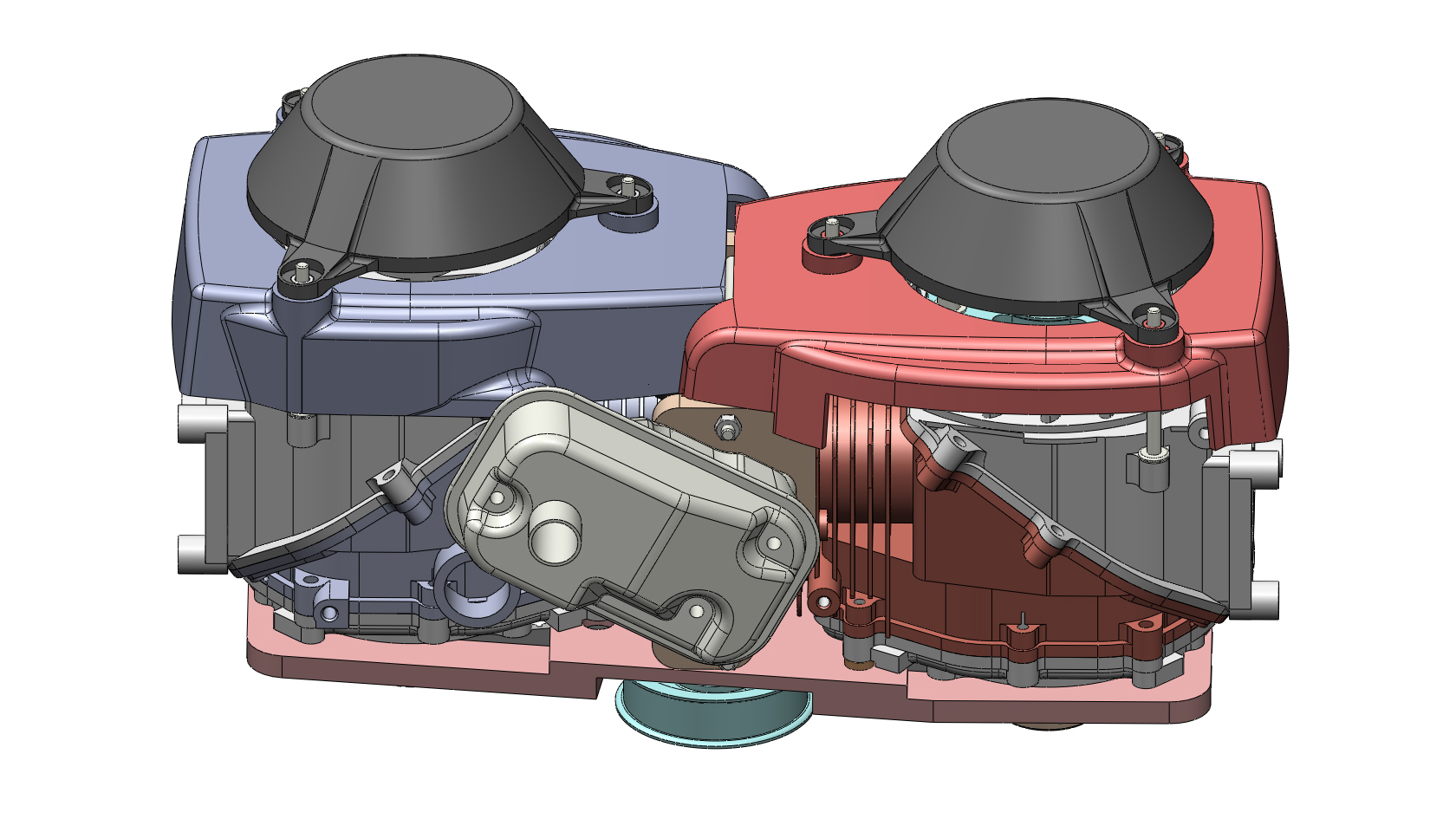

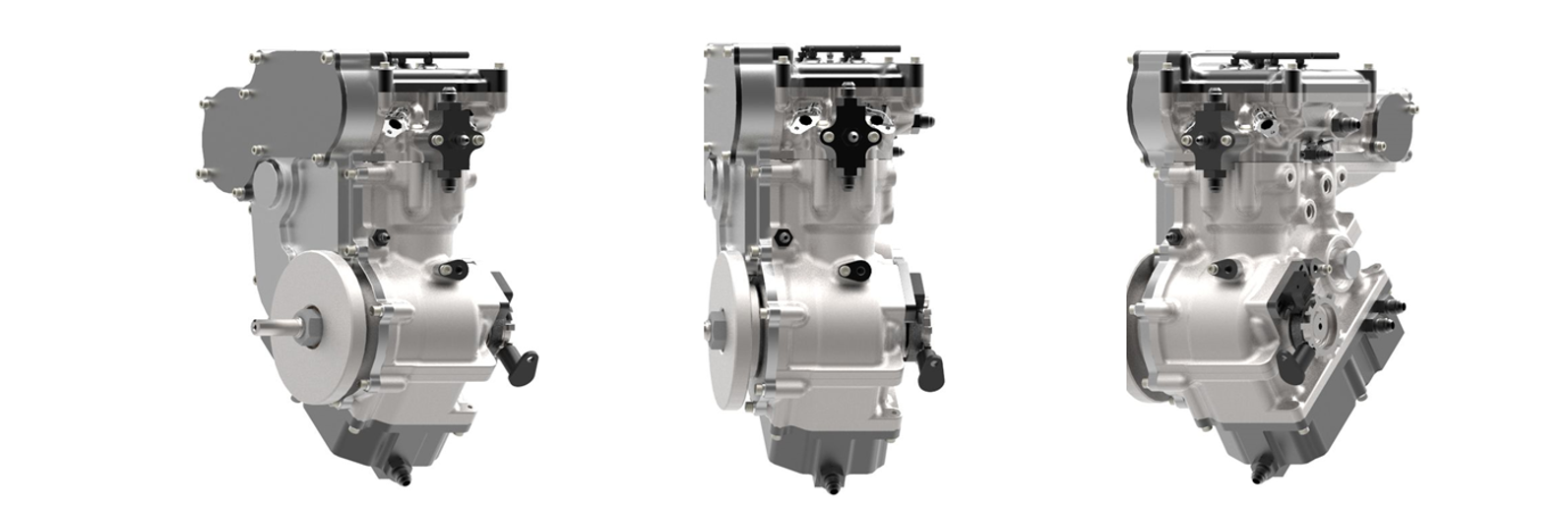

Unlike current combustion engines, which use the same cylinder for all four strokes (intake, compression, combustion, and exhaust), Tour’s patented engine design splits the conventional 4-stroke cycle between two cylinders: the cold-cylinder hosts intake and compression, and the hot-cylinder hosts combustion and exhaust.

A PROPRIETARY CROSSOVER VALVE IS USED TO TRANSFER THE COMPRESSED

CHARGE FROM THE COLD-CYLINDER TO THE HOT-CYLINDER.

This thermal management strategy reduces the magnitude of the two major efficiency losses in

conventional 4-stroke engines – heat loss to the coolant/oil and exhaust energy loss.

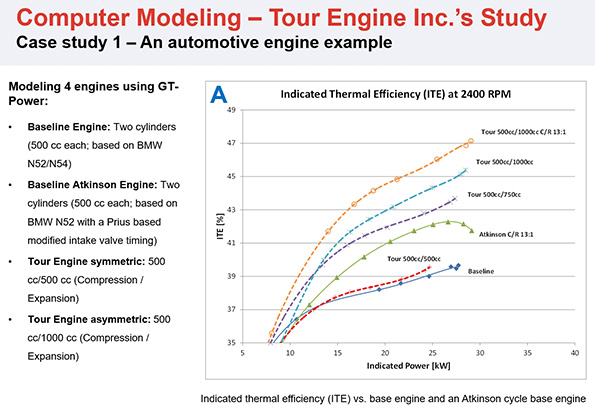

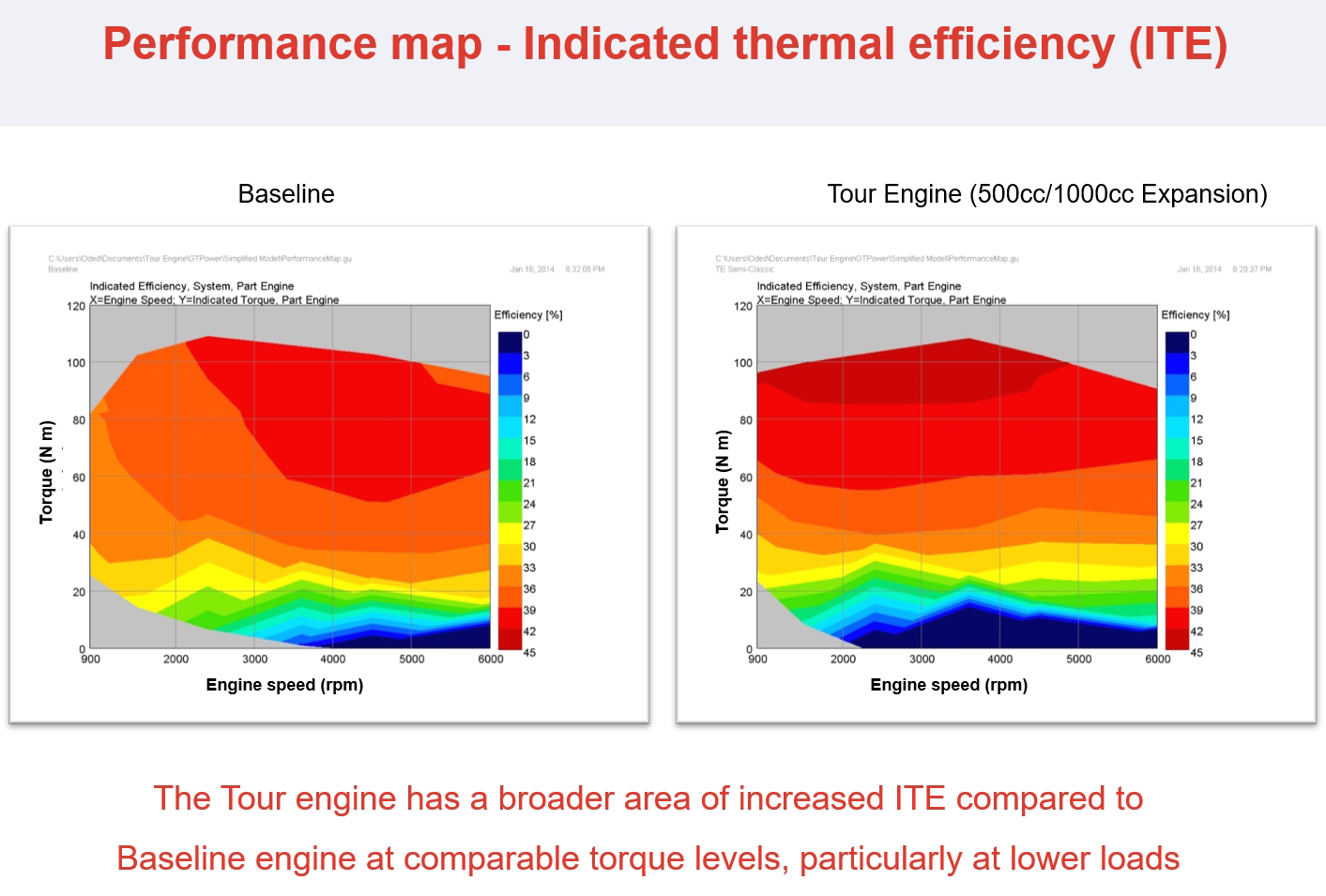

The end result is a thermally optimized engine that advanced computer simulations and working prototypes suggest can be as much as 30% more efficient; dramatically reducing both fuel costs and noxious emissions. Better still, because Tour Engines employ the same “block and piston” architecture that has been at the heart of ICEs for more than a century, they will be inexpensive to manufacture, adopt and maintain.

Learn more about Tour Enable

REIMAGINE THE FUTURE WITH TOUR ENGINE

Tour is backed by sophisticated technology investors and has won grants from both the US (DOE’s ARPA-E) and Israeli (DOE) governments. Tour has also been issued 45 patents (US and International) with several more pending.

LEARN ABOUT MORE WAYS YOU CAN GET INVOLVED WITH OUR TEAM